Advanced Laser Technology for LPBF Processes

YTTERBIUM FIBER LASER Model YLR-3000-1000-AM

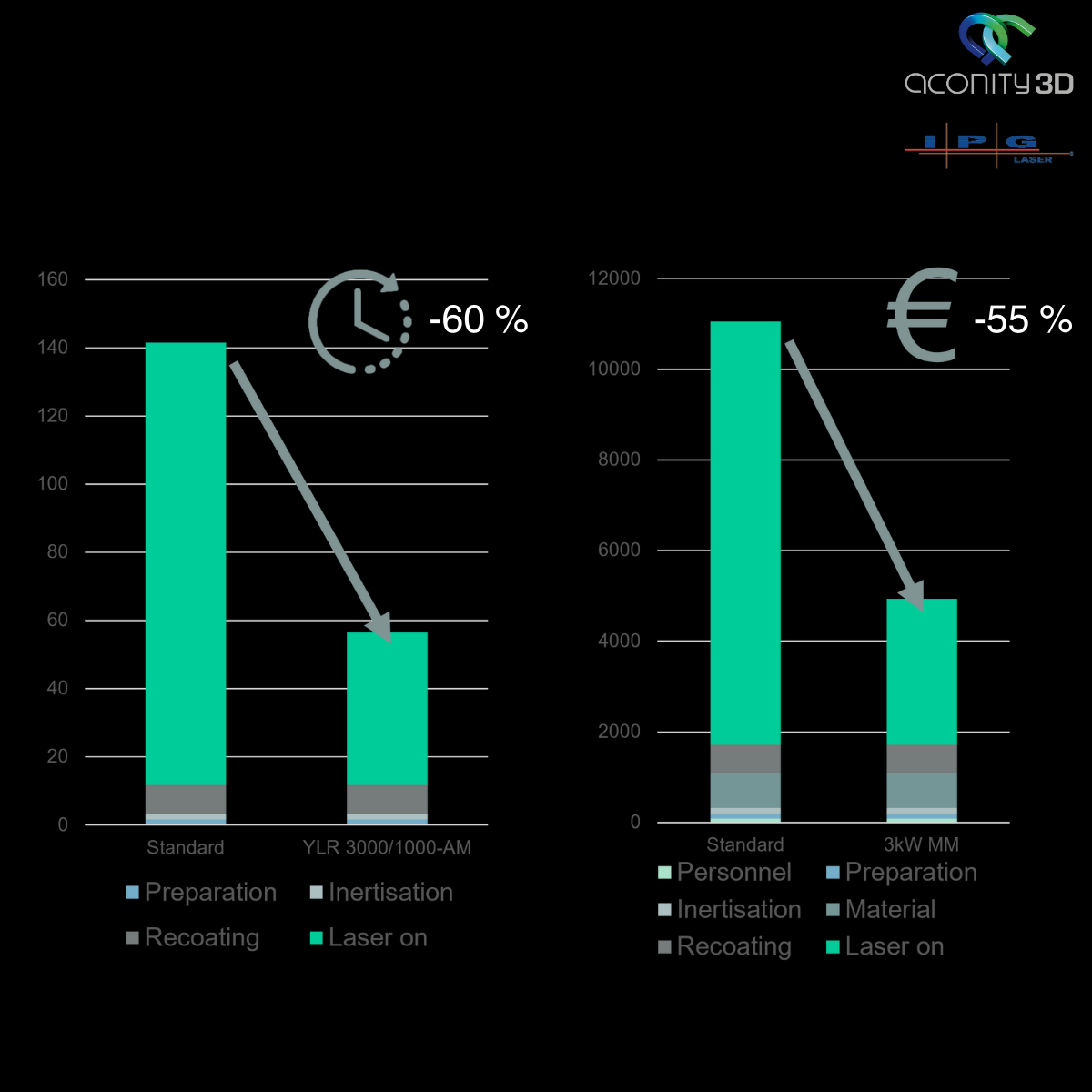

Aconity3D continues to revolutionize the world of additive manufacturing with its latest laser technology, specifically designed for Laser Powder Bed Fusion (LPBF) processes.

Our new offering, the YLR-1000/3000-AM laser from IPG Photonics, stands out with its ability to adapt the intensity profile from a standard Gaussian distribution to a tophat mode, enhancing both precision and productivity.

The YLR-1000/3000-AM laser’s versatility is a game-changer. It enables highly accurate contour scans with its small spot sizes in Gaussian mode, while also allowing for the efficient melting of large-volume component geometries when switched to tophat mode. This dual capability ensures that users can achieve superior quality and speed in their LPBF processes.

Key features of the YLR-1000/3000-AM laser include:

- Unmatched Power: With a maximum output of 3 kW, this laser offers a level of performance that is unprecedented in the market.

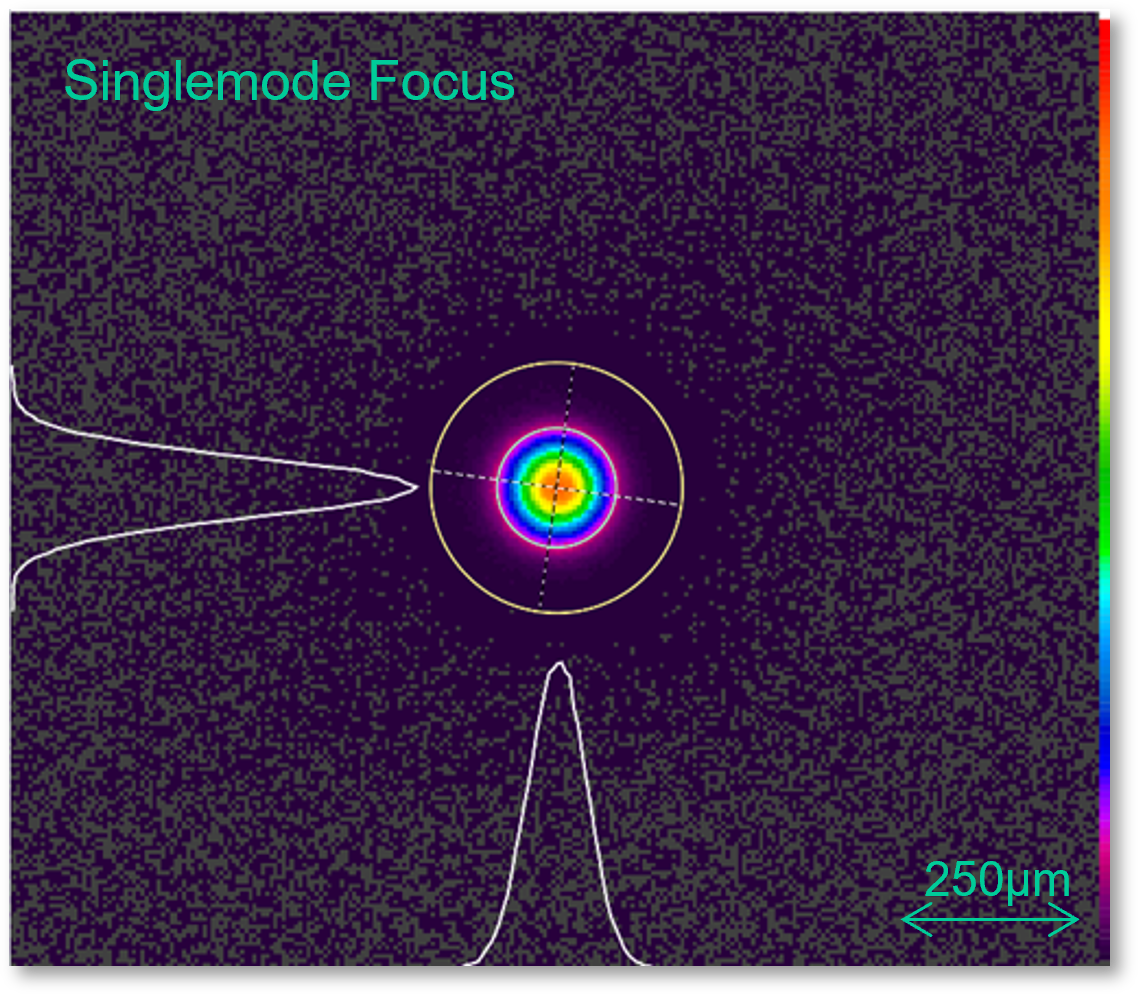

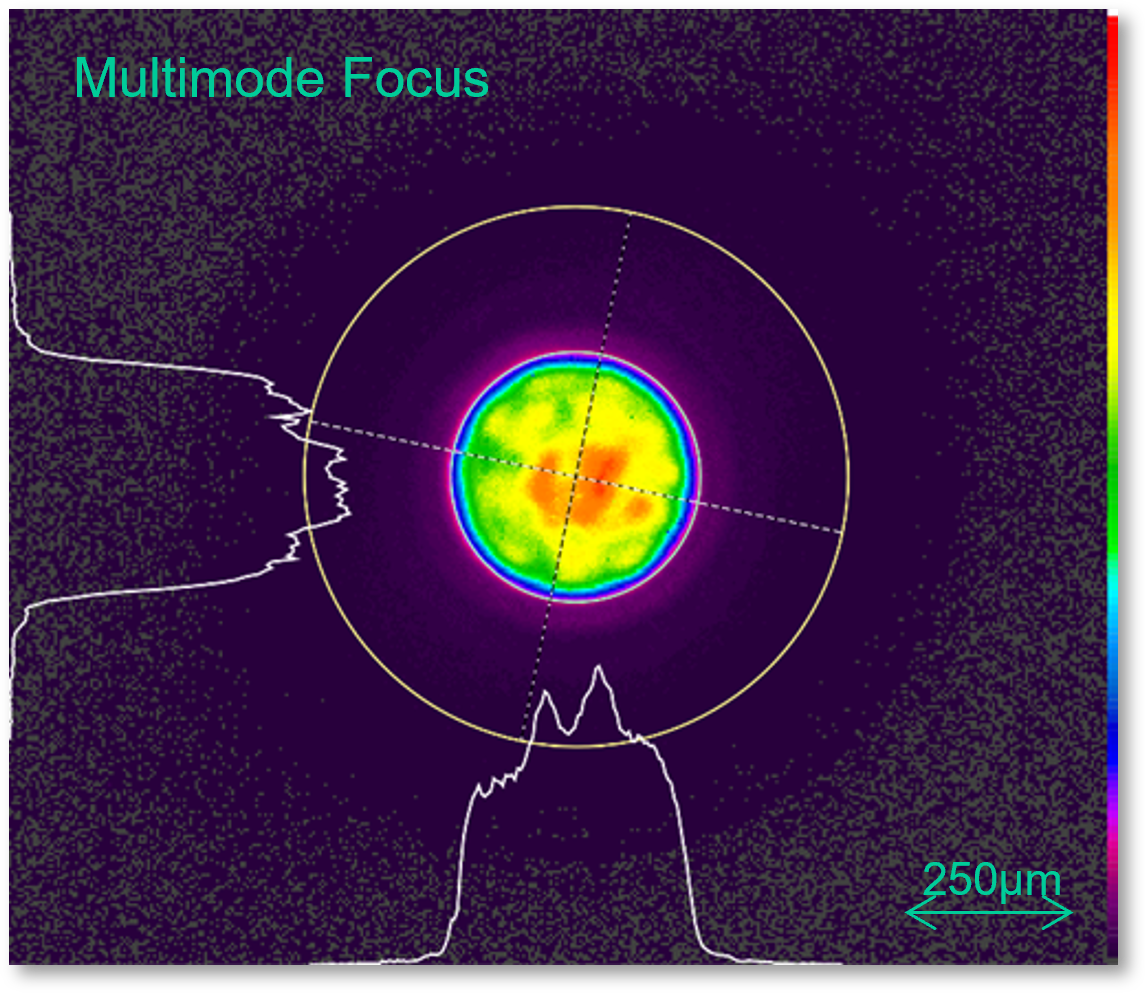

- Programmable 2-step intensity profile: Users can seamlessly switch from single mode Gauss (up to 1000 W) to multi mode tophat (up to 3000 W), tailoring the laser’s performance to specific project requirements.

- Water cooling system: Ensures the laser operates efficiently and maintains optimal temperatures during extended use.

- Optical device coating: All optical components are coated appropriately to enhance performance and durability.

- Spot size versatility: The laser can achieve a minimal spot size of 130 µm in single mode Gauss and a maximal spot size of 390 µm in multi mode tophat, providing unparalleled flexibility in laser applications. Additionally, smaller spot sizes, such as 80 µm Gauss and 240 µm tophat, are available upon request, providing unparalleled flexibility in laser applications.

The YLR-1000/3000-AM laser comes exclusively with AconitySCAN, ensuring users have access to a fully integrated system for their additive manufacturing needs. This combination of advanced laser technology and robust scanning capabilities sets a new standard in the industry, making us a leader in innovation and efficiency in the LPBF process.