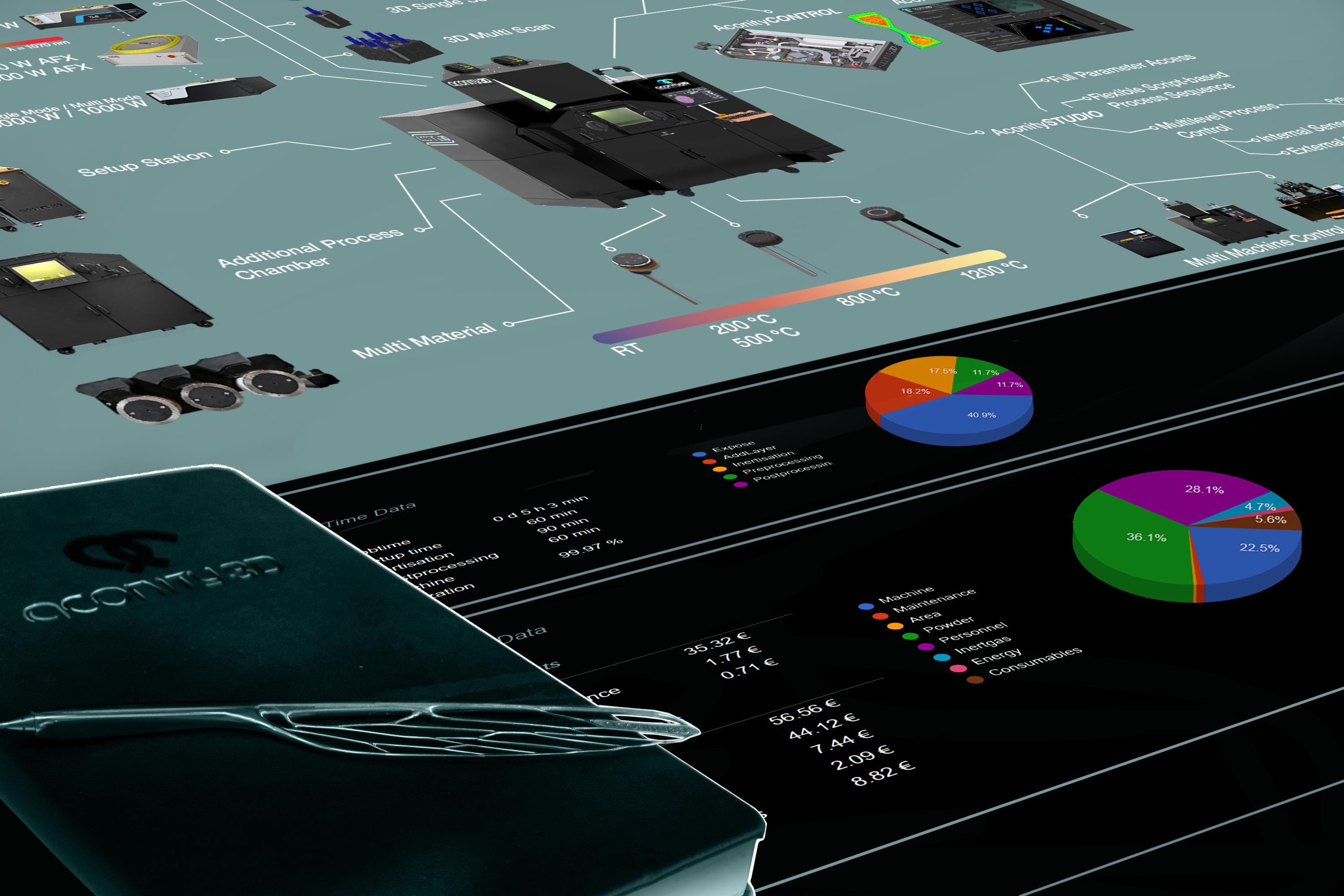

Introducing the Aconity3D Business Case Calculator – Quick & Transparent Part Cost Calculation for Additive Manufacturing

Smarter decisions through data-driven machine selection tailored to your production needs

Our Business Case Calculator is a powerful software tool designed to help you analyze part costs and uncover significant savings potential in your additive manufacturing projects.

Based on your specific application requirements, the tool also identifies the most suitable and cost-efficient Aconity3D machine configuration, but at its core, it’s all about enabling you to make informed, cost-driven decisions.

How it works – in just three steps:

1. Your Application

Upload your CAD file, specify the material, and define your desired batch size.Your Production Environment

2. Your Production Environment

Enter key operational parameters such as depreciation, available floor space, space and energy costs, personnel structure, auxiliary systems, and shift setup.

3. The Result: Part Cost, a Breakdown of Time and Expenses, and the most Cost-Efficient Machine Configuration

Using your data, the tool calculates part costs and highlights the key contributors. This reveals the most effective levers to further reduce manufacturing costs. Additionally, the tool suggests the machine configuration that offers the best performance-to-cost ratio for your specific use case.

Let’s find the ideal solution for your application – together!

Contact our sales team at machines@aconity3d.com or book a meeting directly: https://calendly.com/eibl/30min