Aconity3D Showcases Synced Multi-Laser Processing in LPBF

Multi-laser synchronization reimagined — full operator control directly on the machine

We have released a technology video demonstrating synced multi-laser processing in Laser Powder Bed Fusion (LPBF). The video highlights the ability to select a leading and a following laser beam within one build job, enabling new levels of laser-to-laser interaction and operator-controlled beam sequencing directly on the machine.

This capability is enabled by Advanced Exposure Strategies (AES) – an integrated toolkit for dynamic vector overlay, allowing commanded scan vectors to be superimposed and modulated at extremely high frequencies. AES expands process flexibility with real-time laser control features including frequency modulation, beam defocusing, adaptive intensity profiles, power tailoring, and programmable wobble and scan modifications. This positions Aconity3D at the forefront of next-generation L-PBF exposure and energy distribution strategies.

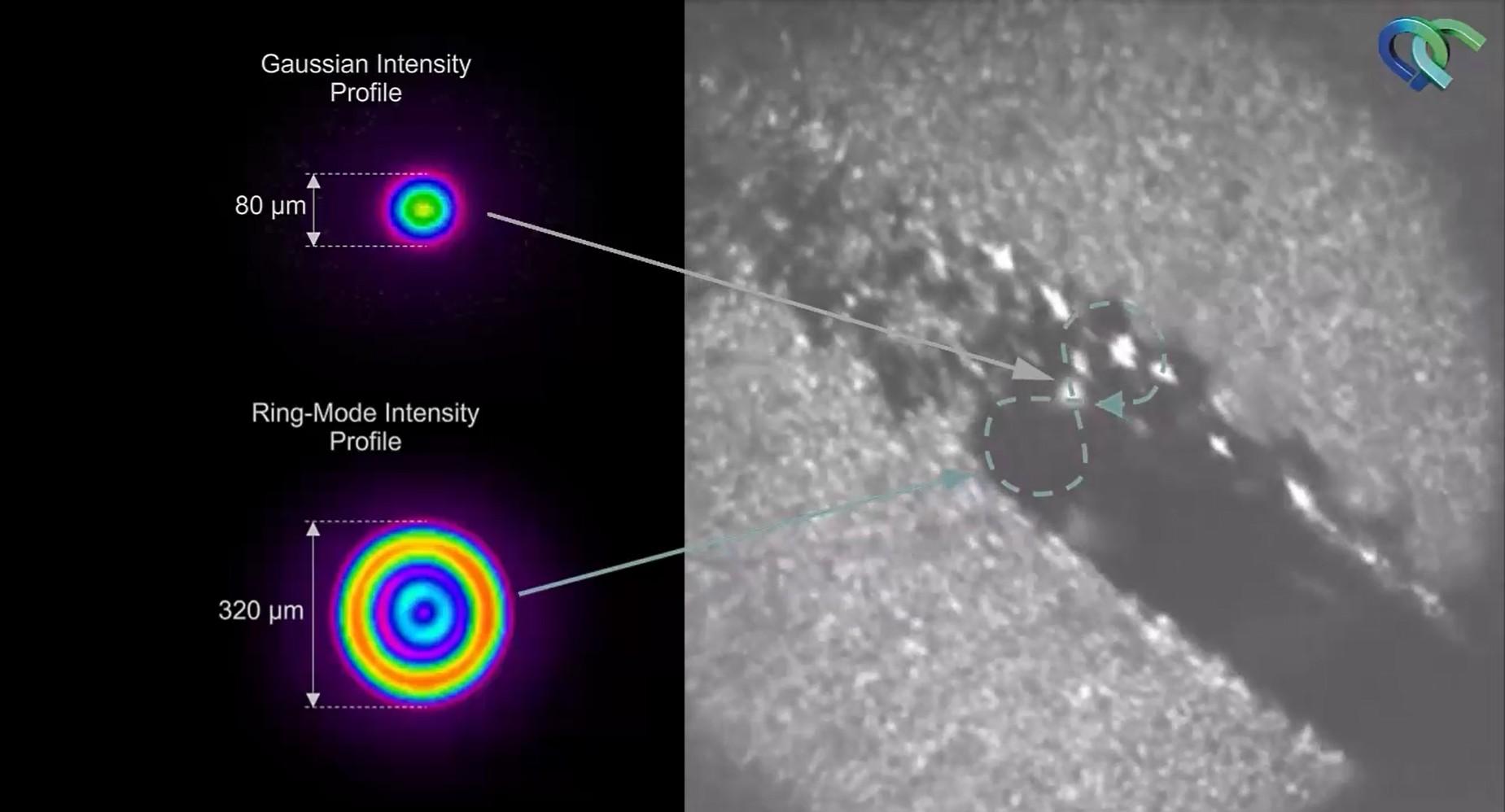

In the showcased example, the processing beam is accompanied with a ring-shaped 1200 W AFX spot in a butterfly tool-path. The high-power ring beam delivers 1200 W of energy and follows a butterfly-shaped tool-path, creating a controlled concentric energy superposition around the primary melt vectors. This demonstrates advanced thermal conditioning and localized energy shaping for improved melt pool stability and targeted process tuning in high-precision laser powder bed fusion systems.

All tool-paths, vector overlays, and laser parameters are configured directly in our AconitySTUDIO control software, running locally at the machine via the onboard control interface. Providing build-system-side exposure programming and immediate operator feedback, AconitySTUDIO ensures maximum process visibility, fast iteration, and superior user benefit, removing external preprocessing steps and giving operators full control over multi-laser exposure concepts, vector superposition, and thermal beam coordination.

By bringing advanced multi-laser vector control directly into machine-level operation, Aconity3D continues to strengthen its commitment to operator-focused process innovation, enhanced usability, and advanced energy modulation concepts for metal 3D printing. Our developments support new applications in research, industrial production, exposure strategy development, and process optimization for multi-laser Laser Powder Bed Fusion technologies.

Watch the video now: