Aconity3D & Cube-Farm – Innovation Rooted in Regional Collaboration

Together for sustainable food: additive manufacturing meets modular farming

When high-tech meets hometown spirit: The partnership between Aconity3D and start-up Cube-Farm demonstrates how regional networks can drive forward innovative projects.

Cube-Farm, a young company based in the Eifel region, develops modular indoor farming systems for sustainable and space-efficient food production. To build their systems, Cube-Farm needed high-precision bearing blocks – and found the ideal partner in Aconity3D.

The connection came about in a down-to-earth way: they knew each other from the region. Enrico Steffens from Cube-Farm and Michael Stockschläder from Aconity3D GmbH both have roots in the Eifel – and a local acquaintance turned into a successful collaboration.

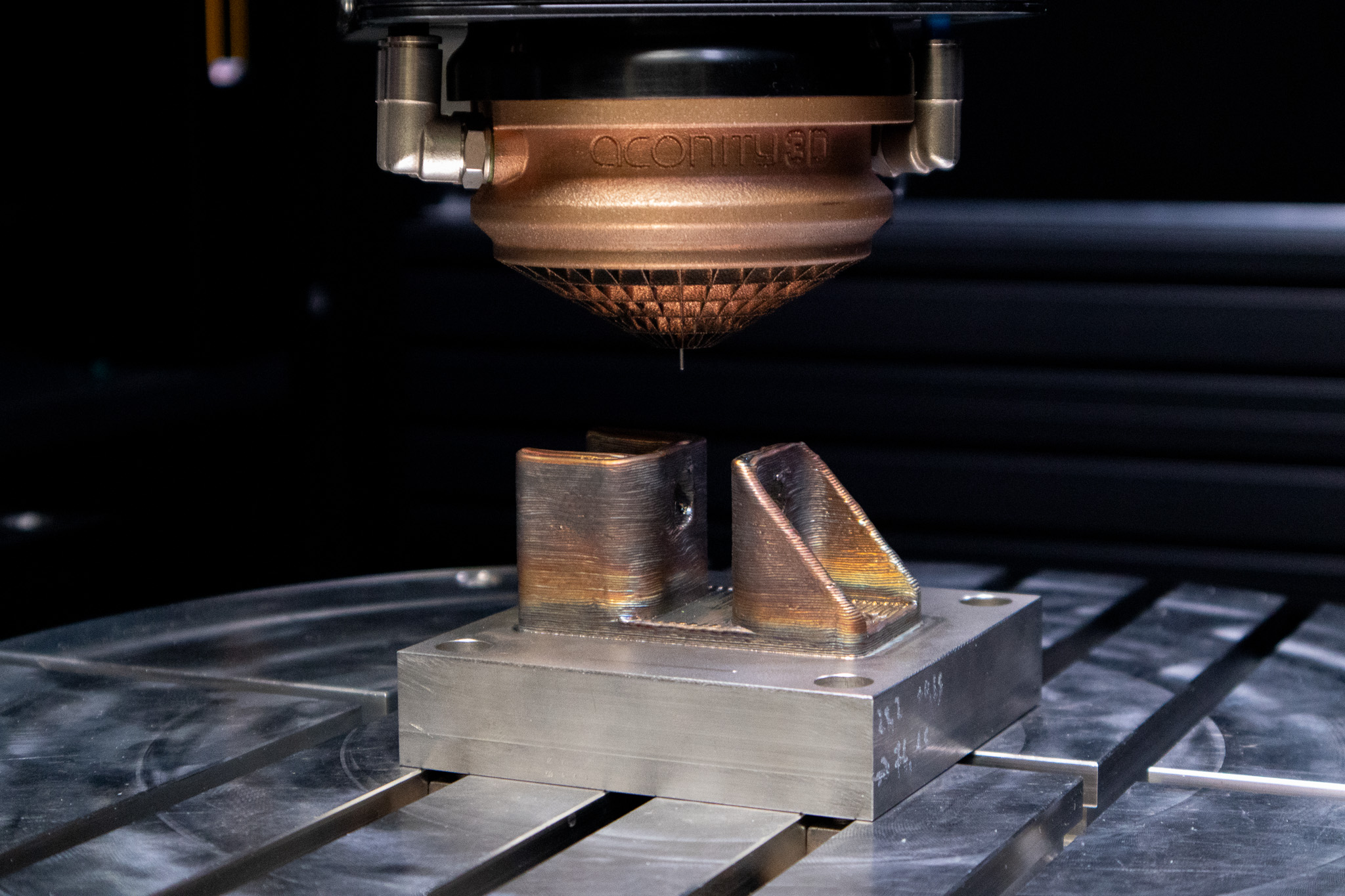

Until now, the bearing blocks were produced using an FDM 3D printer. While this worked for initial prototypes, the parts are not durable enough to withstand the constant load of water and plants in the long term.

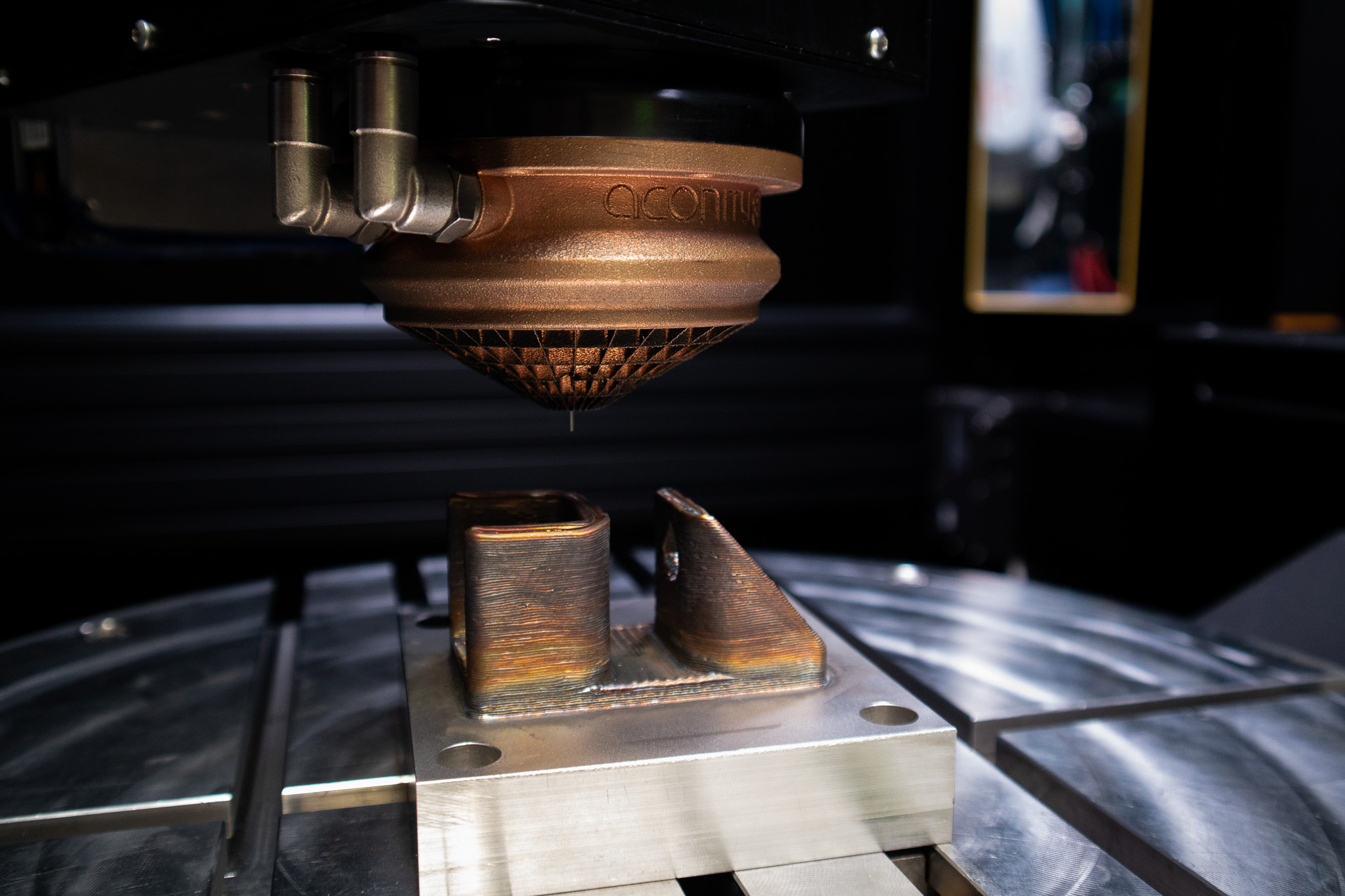

With our AconityWIRE – a machine designed specifically for wire-based additive manufacturing – we now produce custom bearing blocks for Cube-Farm. The benefits: maximum material efficiency, precise adaptation to customer requirements, and a sustainable production approach that aligns with the philosophy of both companies.

Together, we’re proving that cutting-edge technology and regional ties are not mutually exclusiv, but rather the key to future-ready innovation.