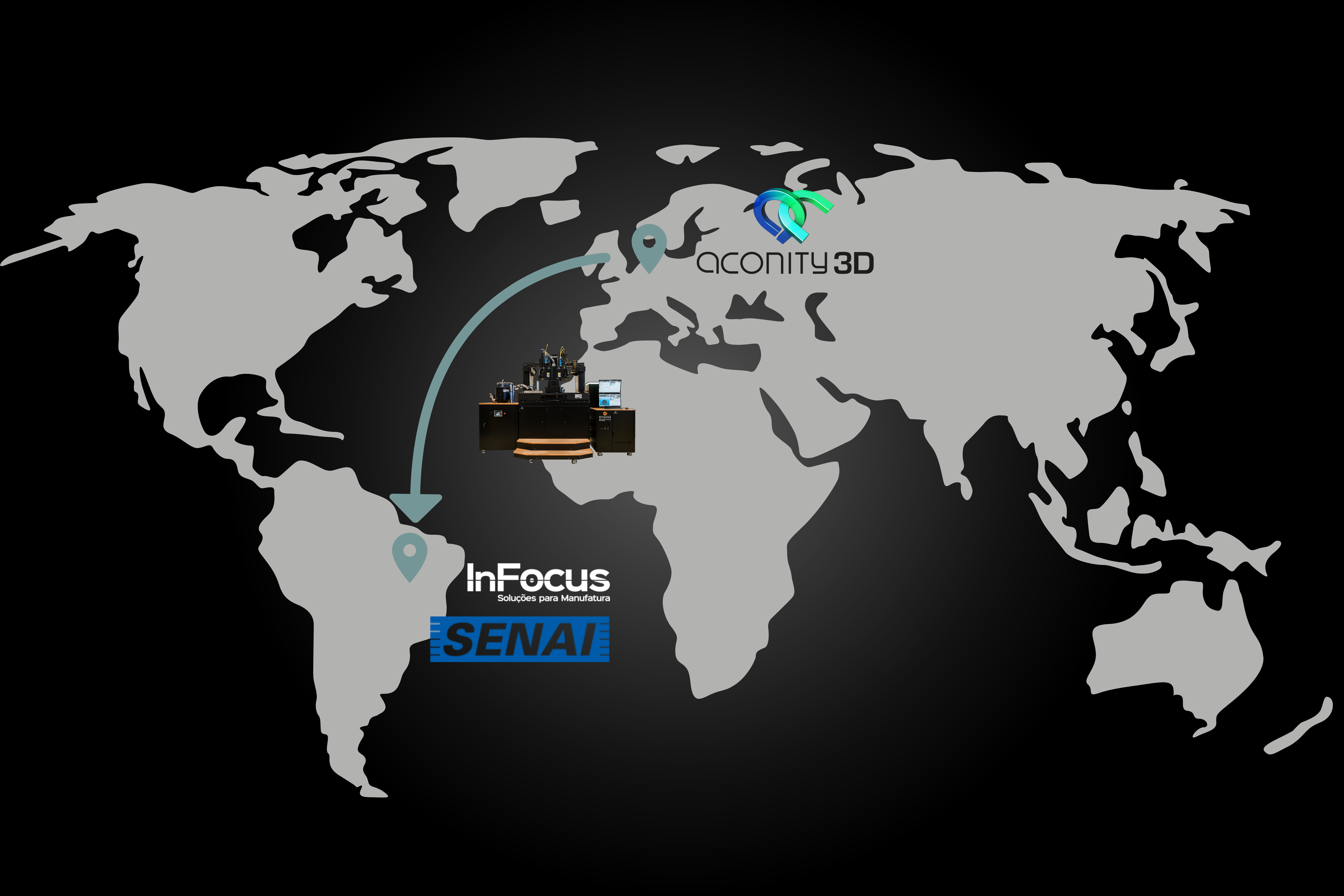

Aconity3D Delivers Aconity𝙏𝙒𝙊 to SENAI in Brazil – In Cooperation with InFocus

Modular 3D printing system with large-format build platform and four-laser technology strengthens industrial AM capabilities in South America

We are pleased to announce the successful completion and installation of our AconityTWO at the Brazilian technology institute SENAI. This project was realized in close cooperation with our local distributor InFocus.

The delivered AconityTWO represents a particularly powerful configuration of our modular AM system platform. With a standard build volume of Ø 400 x H 400 mm and the option to reduce the build area to Ø 200 x H 400 mm, the machine is ideally suited for the industrial production of complex metal components of various sizes.

The installed machine is equipped with the following high-performance features:

- – 4x AconitySCAN 3D scanners with multi-scanner calibration

- – 3x nLight 1000 W single-mode fiber lasers

- – 1x nLight 1200 W AFX multi-mode fiber laser

- – 4x single pyrometry sensors, each assigned to a scanner, with the goal of real time monitoring of the melting pool

- – Inline monitoring for real-time process control

- – Bidirectional powder recoating with a second supplier unit for uniform material distribution and reduced processing time

- – Two build chamber heating systems:

- 500 °C resistive heating (D400 mm, two heating circuits for even temperature distribution)

- 800 °C induction heating (D200 mm)

To further enhance productivity, the AconitySIEVE powder handling system is also employed – including inertization for maximum process reliability, even when working with reactive materials.

“With this exceptionally high-end configuration of the AconityTWO, we are setting a new benchmark for industrial additive manufacturing in South America together with SENAI,” says Marco Weinand, Project Manager at Aconity3D. “We are particularly pleased to have realized this project with such a dedicated and competent partner as InFocus. The close local collaboration was key to the successful commissioning and lays the groundwork for future projects in the region. Combined with the technical capabilities of the system – from flexible multi-laser architecture to integrated process monitoring – we offer our customers maximum control and efficiency.”

With the successful commissioning at SENAI, we are further expanding our presence in South America and supporting the development of cutting-edge additive manufacturing technologies in the region.