With the Digital Twin to “First Time Right” in Industrial 3D Printing

Avoid errors before they occur – through realistic simulation and precise planning

The vision of additive manufacturing as a sustainable, flexible, and highly precise production technology depends entirely on process reliability.

That is why, together with SWMS Systemtechnik Ingenieurgesellschaft, we rely on virtual process validation through digital twins.

The path from CAD model to finished metal 3D-printed part is complex: what sounds linear in theory poses significant challenges in practice – countless process parameters, high resource costs, energy-intensive production steps, and CAM systems that only provide an idealized emulation of the machine environment, but do not represent the real process dynamics. Defective parts drastically reduce ecological and economic benefits throughout the entire product lifecycle.

What if you no longer had to accept costly misprints in additive manufacturing?

“First Time Right” has so far been more of a dream goal, but with digital twins, this vision is coming within reach. They build the bridge between idealized theory and the real conditions of industrial practice.

According to the European Commission, additive manufacturing is not only pioneering but already recognized as a sustainable, resource-efficient, and precise production technology. However, its ecological and economic benefits depend entirely on process reliability.

Therefore, Aconity3D, one of the leading providers of industrial 3D printing systems, collaborates with SWMS Systemtechnik Ingenieurgesellschaft to implement virtual process validation using digital twins—an intelligent contextualization of digital simulation and real manufacturing.

The path from CAD model to a functional metal part is anything but straightforward: countless process parameters, energy-intensive steps, high material costs, and CAM systems that often only idealize the machine environment make error-free production a balancing act. Defective parts not only reduce productivity but also undermine the sustainability advantage across the entire lifecycle.

Digital twins represent a paradigm shift here – they enable reliable predictions, optimized process control, and create trust in a production where quality is no longer a matter of chance.

From design to perfect part: Efficiency, sustainability, and defect-free production—are they a matter of design?

The answer lies in virtual commissioning: digital twins make possible what was previously hardly achievable—a realistic mapping of the entire manufacturing process before the first material is applied.

Together with SWMS Systemtechnik, an experienced technology partner for industrial software applications, Aconity3D has now reached a milestone: the digitization and virtualization of the AM process through digital twins. SWMS’s core competencies – Knowledge Based Engineering, CAx automation, and path-based process planning for AM and AFP—enable a realistic simulation of manufacturing, including:

- – Collision checking

- – Axis limits

- – Material deposition

- – Singularity detection

While classical CAM systems deliver only a static emulation, the digital twin goes one step further: it maps the physical dynamics of the real system. The virtual environment encompasses both machine behavior and manufacturing programs—becoming the digital shadow of the real process.

This makes the digital twin not just a technical gimmick in research, but a strategic tool in industrial practice: costly misprints are reduced, downtime minimized, and valuable resources saved. A real step toward “First Time Right.”

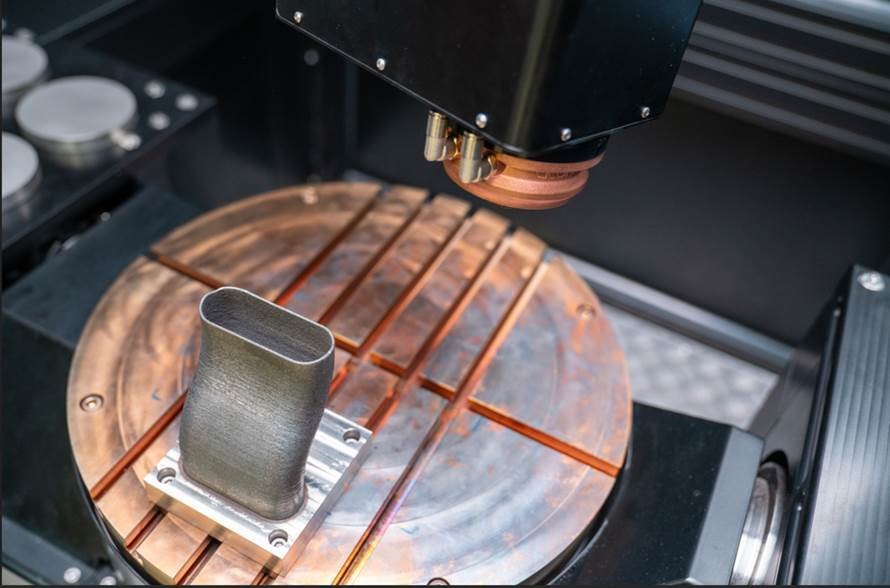

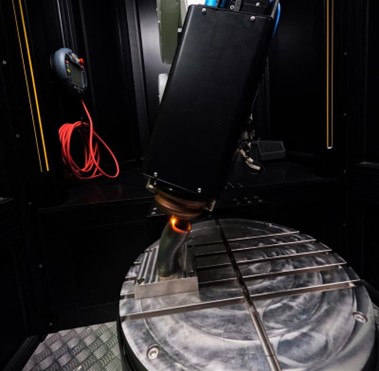

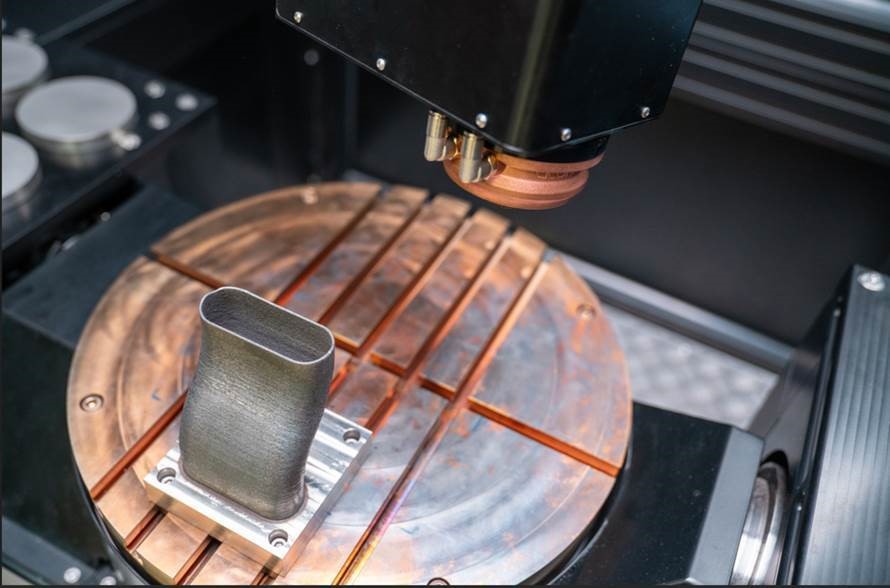

Digital Twin in Action: Demo Part as a Benchmark for Process Reliability

The complex, curved geometry of the part poses significant challenges not only to the software but also to the machine. Without digital simulation, faulty material deposits and imprecise layer transitions would quickly have resulted in scrap. A risk that can be detected and avoided early thanks to the digital twin.

A particularly demanding demo part—with curved, non-planar geometry pushing conventional layer strategies to their limits – served as a test object for the digital process chain. Preparation was done in Siemens NX, with export via a post-processor developed by SWMS. This example demonstrates how digital twins enable precise process planning even – and especially – for complex geometries, saving resources, time, and costs. The challenge: continuously adjusting layer height through precise variation of laser power and wire feed required the highest accuracy.

A perfect example of how tightly digital planning and real manufacturing must be linked to achieve reliable results.

“First Time Right” is more than just a buzzword – it is the key to sustainable and economical additive manufacturing

In additive manufacturing, precise process planning is crucial – it determines whether a part is successfully produced or ends up as costly scrap. Every avoided misprint saves expensive resources and energy, reduces downtime, and increases planning reliability – a clear competitive advantage for companies.

By seamlessly combining toolpath planning in Siemens NX with subsequent validation in AconityCOMMAND, errors can be detected and avoided early. This contributes significantly to resource conservation and energy efficiency already in the planning phase. The result: less scrap, shorter downtime, and an improved ecological footprint.

“Our goal is batch size one – without compromises on quality, sustainability, or economy,” explains Michael Stockschläder of Aconity3D. “With the digital twin as an intelligent planning partner, we are a big step closer to making First Time Right a reality.”

This development is accompanied by the Additive Manufacturing Lab at Rosenheim Technical University of Applied Sciences, which ensures through scientific expertise that the latest findings flow directly into industrial application.